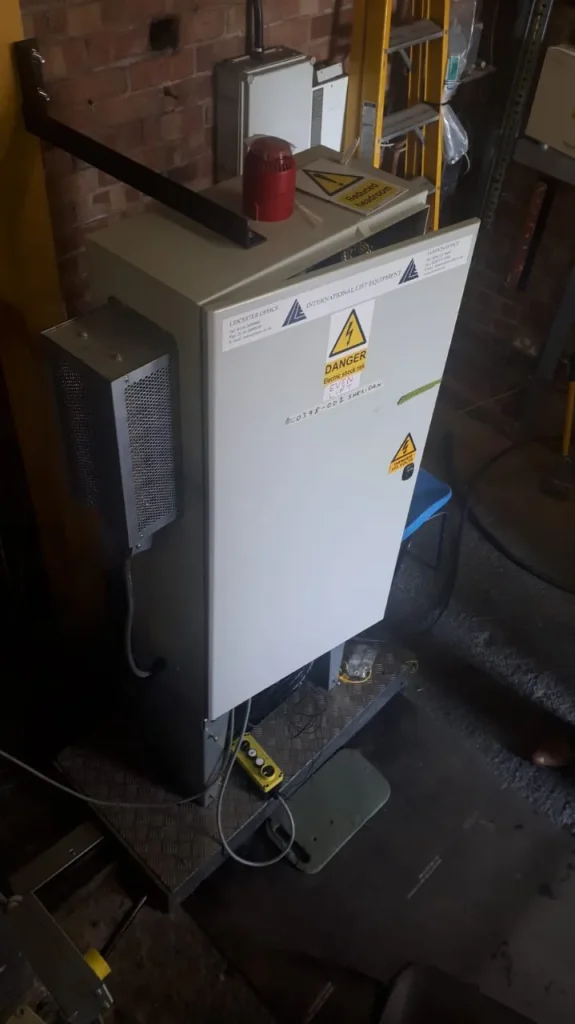

Our Sheridan Lifts engineering team disabled the motor room lift controls and stripped these out completely. We replace with a new controller, bed plate and motor, all with high quality low smoke and fume, fully specified cabling and trunking. The counterbalance is suspended, and the lift car safely landed. The remaining contents are stripped away and then replaced with the new equipment. Optimum care is taken to fit the safety systems employed on all lift projects.

The next step was to carry out the re-rope and preliminary re-wire before ‘firing up’ the motor and we could use this as a safe working platform. Then we commenced work on the lift entrances.

At this point, the specialist trades come in and measure up for new architraves. These hand-built stainless steel architraves are constructed and eventually backfilled with full consideration to become part of the fire rating and to fully sustain a long lifespan. In these works, there is concrete poured into the architraves for them to achieve fire rating and create sustained lifespan durability.

Final works will entail switches, secondary wiring looms, trailers, CCTV, indicators, fireman’s control and making good all landings to the high standard that matches the finish on the rest of the building. Builders’ works will entail ramping the floor (+25mm for a firefighter) and commissioning the Sump Pump system within the Pit. Car interior, COP and the car floor will be completed.

Then the lift is ready to test! This will take however long is required, with test weight ratios and a detailed program of testing that sits within the mandatory fields of a firefighter lift.